Why did LEGO make a 3D printed piece?

The new LEGO Icons Holiday Express Train has a new and very unique new LEGO element! No doubt you know what it is and that’s why you’re reading this, so let’s discuss why!

So a little bit of background first. This isn’t the first time the LEGO Group have done a 3D printed element. But it is the first time they have done it in a LEGO Retail set. Meaning a LEGO set that’s made on a larger production run and easily available.

The first time the did a 3D printed element was in 2019, in LEGO set 4000034, the LEGO Insiders Tour set. It was part 66237, a utensil drafting table arm. It has a little bit of movement in it and a unique shape that would be rather difficult to recreate in standard LEGO bricks in the same way. You can see New Elementary‘s video of it here.

Next time we saw a 3D printed LEGO element was in 2022, a LEGO Duck that was given to LEGO House AFOL Day 2022 attendees. It is super hard to get, unless you’re willing to drop some big $$$ on Bricklink. But the LEGO Duck has a moving beak when you push it.

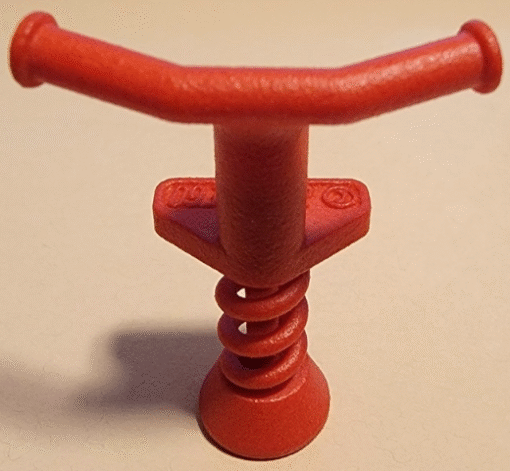

And another, the LEGO 3d-printed Pogo Stick, a reward for crowdfunding ‘The Secret Life of LEGO Bricks’ book in 2022. The springs on the Pogo Stick actually move and flex which is very impressive!

So what do all of these LEGO 3D printed elements have in common…? They move!

Photos: Bricklink, New Elementary & Jay’s Brick Blog.

But Why 3D Print Them?

Plastic LEGO elements are injection moulded. With injection moulding, there are restrictions on what is possible. Once the plastic pellets are melted, the plastic liquid is injected into the mould. This allowed LEGO to create complex, detailed shapes with a high level of consistency and quality.

But injection moulding comes with limitations. There are size restrictions, thickness issues, complex shapes etc.

This means there are things a 3d Printer can do that an injection mould can not.

For example, think of a chain link. To do this with injection moulding, you would need to mould 2x C-shaped elements, which are then connected together to make an O-shape. You would then have to connect those C-shapes together through the O-shape to make the chain.

But with 3D printing, it is able to print the O-shape as one piece, and then print the 2nd O-shape in one piece, interlocking it with the previous one.

How does this relate to the 3D printed train in the LEGO Icons Holiday Express Train?

3D Printed Train

The 3d train in the LEGO Icons Holiday Express Train is tiny, around the same size as a 2×4 LEGO brick.

It’s made up of 6 parts. The train body, front wheel and axel (one piece), rear wheel and axel (one piece), the left and right wheel rods and the beam that’s attached to the front axel running up the chimney.

All of these pieces have been 3D printed together as one. Referring back to the C-shape chain example, the train essentially does not require assembly. There are no piece that need to clip into others. No clipping together.

With 3D printing, it’s all able to be done in one piece… But kind of separate pieces. It’s almost like knitting it together I guess?

As you can see in the pictures, the front wheel and axel is different to the rear. The axel has a U-shape bend in it (4th picture), which has the chimney beam attached. This is so when the wheels turn, it pumped the beam up and down inside of the chimney.

Take note of the wheels as well. The wheel and axel are one solid piece. Which would be impossible to get through the axel hole without creating a suitable gap or break point in the plastic.

Will 3D printing take over normal LEGO bricks?

Simply put, no.

Injection moulding is quick, cheap and much higher quality. Even for the LEGO Group to make this 3D printed train on a mass scale and to their high quality standards, it would have taken so much longer than any injection moulded element. I dare say it would have cost them a lot more as well.

Is it the last 3D printed element we’ll see?

Also no. It is clear they have been testing the waters for a while. I would say they will dabble here and there to provide cool little elements to sets just like they have done in the LEGO Icons Holiday Express Train.

Regardless, it’s an interesting space to keen an eye on to see how the LEGO Group plays with 3D printing in the future.

Please check out our hands on review of the LEGO Icons Holiday Express Train set here!

Thank you for reading

Support BrickBanter.com by shopping for your LEGO® via the affiliate links below.

It’ll cost you nothing but will mean the world to us. 🫶

🇦🇺 Australia – 🇨🇦 Canada – 🇪🇺 Europe – 🇬🇧 United Kingdom – 🇺🇸 United States – 💛 Everyone else

Explore more articles

BrickBanter.com is a recognized LEGO® Fan Media account.

Review sets are supplied by the LEGO group.